Wind power blade of large-scale, lightweight and reduce the cost of the future development trend has become, which further need to use the material use, product structure design, molding and processing technology innovation and development trend. At this stage the mainstream products of wind power blade material for E glass fiber reinforced plastic material fiber and S glass fiber reinforced plastic material, carbon fiber material enhancement material, light weight, high strength, can reach the wind power blade development trend requirements.

And glass fiber reinforced plastic (FRP) is also called GFRP, that is, fiber-reinforced plastic, generally speaking, refers to the use of glass fiber reinforced polyester, epoxy resin and phenolic resin matrix, to glass fiber reinforced plastic or its industrial products for reinforcing materials, become glass fiber reinforced plastic, or become glass steel, is the production and processing of wind power blade often with materials.

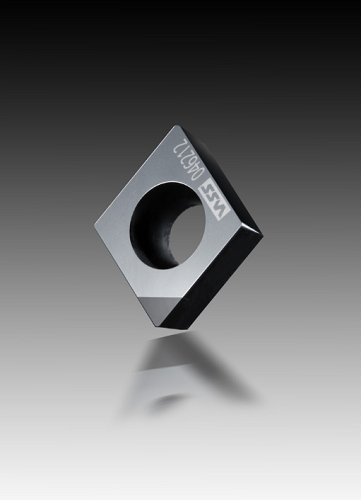

For FRP, PCD tools are the preferred material for the production of FRP at this stage. Four configurations of PCD standard turning inserts, PCD milling cutters, PCD end mills and coated PCD tools are often used for the production of FRP.

|

|

|

PCD ROTARY CUTTING TOOLS

|

PCD STANDARD TOOLS

|

The wind turbine blades have a very large external dimension and are generally made from the integral casting of fibres of FRP material, after which they come to be cut, ground and polished, milled and reamed and other processes of production and processing.

The wind power blade processing technology is mainly vacuum injection molding, molding after the root flush cutting → root end grinding polishing milling processing production processing → root punching → spraying, commonly used to PCD saw blade cutting blade root, PCD face milling knife to carry out end milling production processing, PCD blade or PCD reaming tool to carry out blade root punching production processing.

Machining with drilling equipment with WSS full veneer PCD inserts