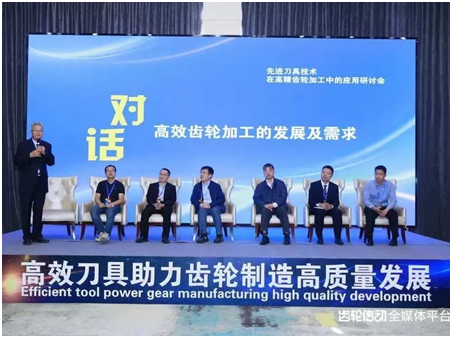

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining

2023-12-06

On 23rd October, 2023 Advanced Tooling Technology in High-Precision Gear Processing Seminar was successfully held in Shanghai, which was organised by Gear Transmission Media Platform under the support of Machinery Transmission Branch of CMAI. The seminar gathered many top experts in the field of gear manufacturing and gear cutting tools from home and abroad, such as Faster, South High Gear, Taiyuan Heavy Industry, CITIC Heavy Industry, Wanliyang, AVIC Dong'an Engine, FAW Jiefang, AeroDevice Western Control, Schaeffler, BorgWarner, Hanjiang Tools, Hengfeng Tools, Chengdu Tool Research Institute, Oerlikon Barchas and Shanghai University of Science and Technology, Shanghai Jiao Tong University, Chongqing University, Shandong University, Shaanxi University of Science and Technology and Shanghai University of Engineering Technology, as well as many experts in the field of gear manufacturing and gear cutting tools, such as the Chinese and foreign experts. and gear cutting tool field top experts, as well as industry users and media representatives totalling more than 150 people, 12 speakers experts around the dynamic characteristics of machine tools, aviation gear manufacturing, cutting tool materials, coatings, applications and other areas of technology were made a conference report, introduce the relevant research results, to share the research experience, and how to accelerate the promotion of gear processing in the key challenges to improve the efficiency of gear manufacturing, the high-quality development of gears Efficient Manufacturing Technology.

Technical exchange and discussion in front of the WSS stand

WSS attended the conference with its Differential Rings, Sun Wheels and Transmission Gears machining solutions, and conducted in-depth technical exchanges with the gear machining industry experts and senior practitioners on site.

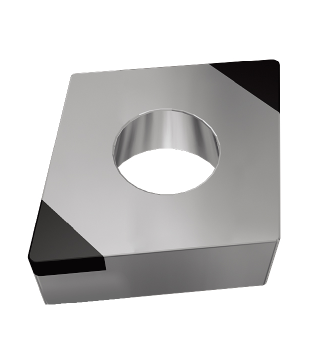

WSS CBN tools for hardened steel cutting are capable of hard turning of gears in a wide range of conditions.

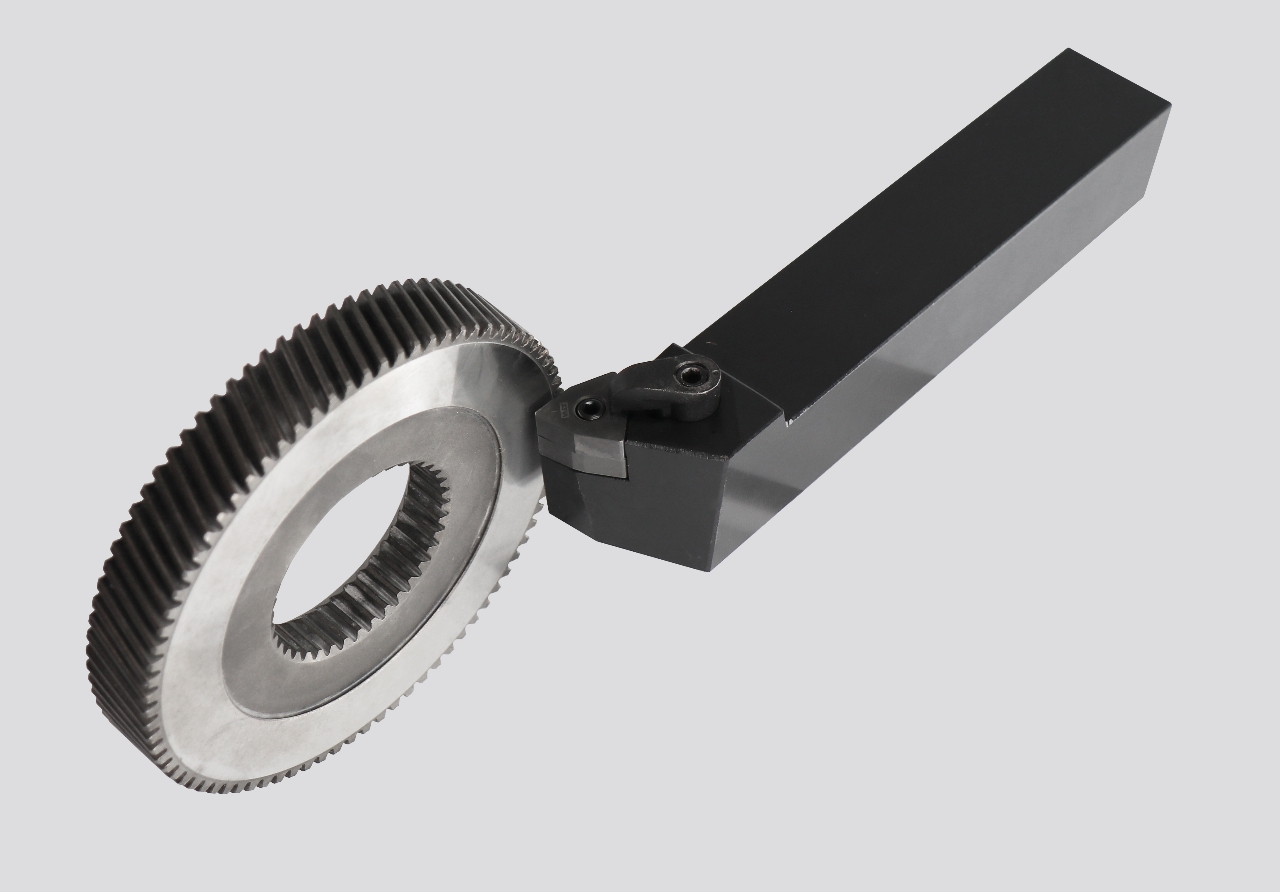

Differential gear ring face and bore machining with one cutter

◾ Rough turning for efficient removal of the carburised layer

◾ Precision turning to ensure dimensional accuracy

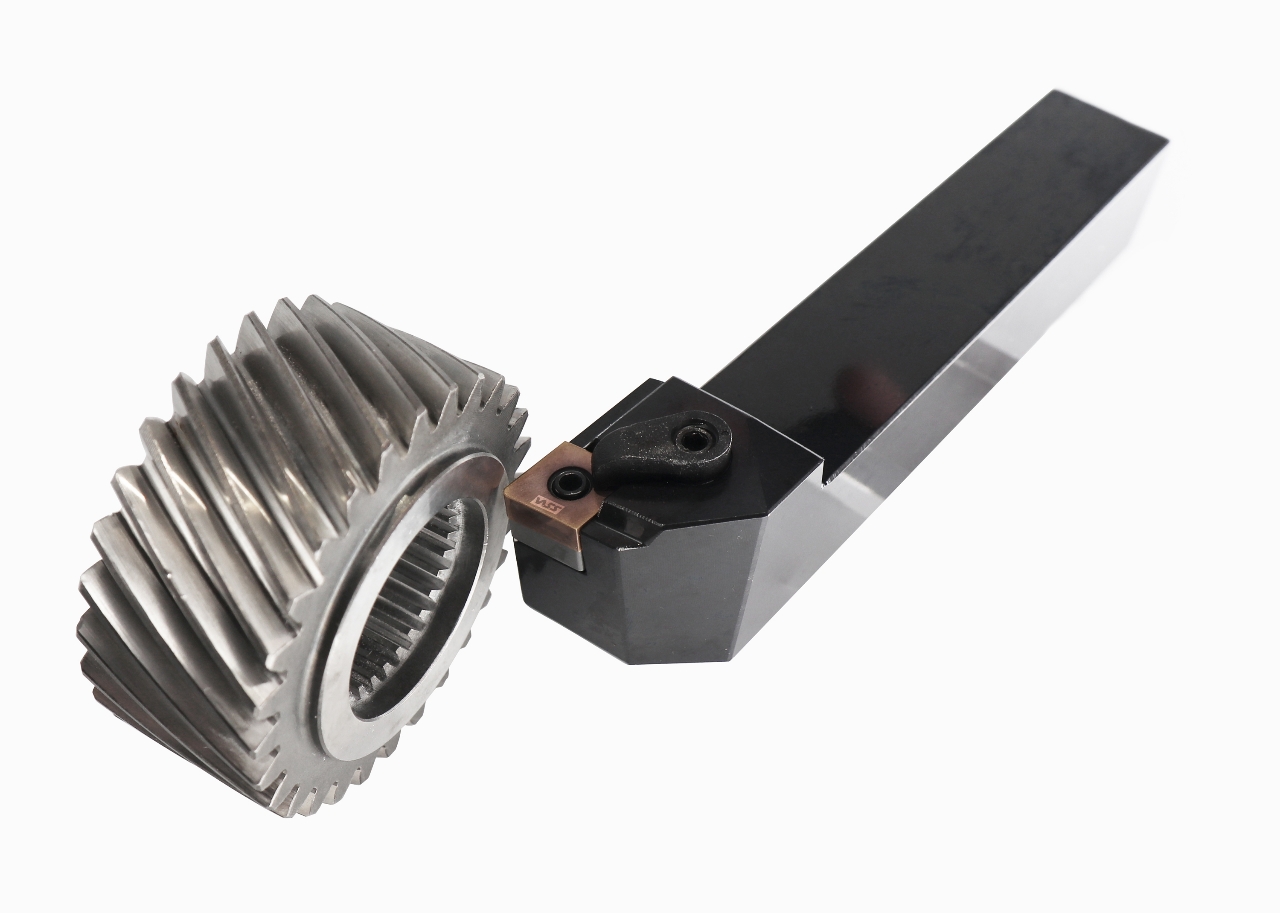

Sun wheel end face machining

◾ Stable and efficient machining

◾ Bright and smooth end face

Gearbox gear end face finish turning

◾ High turning line speeds and significant increases in machining efficiency.

|

WSS is a CBN cutter grade developed for machining heat-treated, high-hardness gears: |

|

|

1 |

Better toughness for higher machining requirements such as heavy loads and intermittent machining. |

|

2 |

High degree of wear resistance, higher tool life, reducing the cost of machining a single workpiece. |

|

3 |

Good heat resistance, impact resistance, suitable for continuous machining, improve the production rhythm |

|

4 |

Provide customised services, such as adding chipbreaker, sharpening edge, etc. |