Since 2011, China has become the second largest medical device market in the world after the United States. The medical industry is closely related to the life and health of all human beings, and the growing importance people attach to health has led to the booming development of the medical industry, which includes implantable medical devices such as bone nails, bone plates, artificial joints and prosthetic limbs. Implantable medical devices belong to the high-end products of the third category of medical devices and are one of the important product categories in the medical device industry.

Implantable medical devices are one of the effective means of treating cardiovascular diseases and orthopaedic diseases. However, the overall technology level of domestic implantable medical devices is low, and high-end implantable devices still need to rely on foreign imports. Therefore, the development and advancement of domestic medical implantable devices cannot be delayed, and implantable devices also place higher demands on machining equipment and tools. Usually, implanted medical devices are partially or fully inserted into the human body or natural cavity with the help of surgery, and the implant will remain in the body for a long time after the surgery. The materials used for these implanted medical devices are special and represent a completely different field for machining.

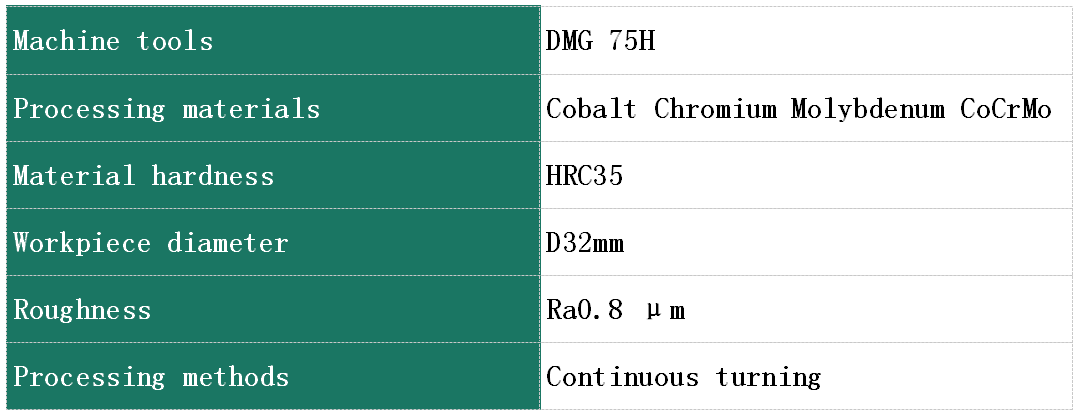

The most common materials used for medical implants include stainless steel, cobalt-based alloys, titanium alloys, polymers, polymers, ceramics, etc. Of these, cobalt-based alloys (cobalt-chromium-molybdenum CoCrMo materials) are widely used and their processing applications are developing most rapidly. As a material with high wear and corrosion resistance, cobalt-chromium-molybdenum also has the advantage of high fatigue resistance and high tensile strength. The alloys of this material are particularly susceptible to work-hardening and the high heat generated during machining places very high demands on the performance of machining tools.

WSS has been developing and improving tools for medical device machining in order to provide better solutions for manufacturers in the medical device industry. Taking the machining of bone and joint parts as an example, WSS has successfully developed CBN tools for the machining of cobalt-chromium-molybdenum CoCrMo alloys and PCD tools for the machining of polyethylene materials, which have been successfully applied to the machining of related materials in the medical field, overcoming some of the technical difficulties in the machining of difficult materials and reducing costs without reducing efficiency.

WSS uses DCGW11T304 custom CBN inserts for external and profiling cuts. With the same cutting parameters, performance is improved by 25% and the quality of the machined parts is consistent.

The WSS uses VBGT160402 PCD inserts to compare machining with existing tools, optimising machining parameters, improving machining efficiency and achieving a consistent tool life of 1500 pieces.