Free from chip entanglement! Chipbreaker CBN tooling applications

2023-05-09When CBN was first developed as a superhard tool material for cutting, it was not designed with chipbreakers, but only with negative chamfers and blunt circles to strengthen the tool itself and to meet the needs of different machining applications.

There are three main reasons for this:

The materials to be machined are specific and do not pose a problem in terms of chipbreaking, such as hardened steel (hardness around HRC 58-62) finishing and rough finishing of cast iron.

The CBN material itself is very hard and the production process is different from the conventional carbide method of opening and pressing the grooves, which requires the intervention of other new methods and makes the creation of chipbreakers relatively difficult.

Tools made from CBN need to maintain a certain level of strength to ensure that when cutting, the CBN material does not chip or micro-chip easily, resulting in a shorter tool life, and its negative chamfering and blunt rounding design helps to increase the strength of the tool itself.

However, in recent years, with the gradual diversification of the materials to be machined, the application of CBN tools to cutting and machining conditions are also very different, mainly encountered the following two difficulties make the design of chipbreaker CBN inserts came into being, but also improve the CBN tool product library, can fully meet the rich and varied machining needs.

01

The hardness of some parts is different after heat treatment according to the required requirements and is usually between HRC 45-55. At the same time, such workpieces have very high requirements for machining efficiency, surface quality and dimensional accuracy, for which CBN tools are suitable. Due to the relatively soft material, there are often problems with chip breakage and chips can easily become entangled in the tool body or workpiece, leading to breakage or scrap. The machined surface is also susceptible to chip scoring, making it impossible to meet the surface quality requirements.

02

There are some parts that still need to be rough machined after heat treatment, the machining allowance usually exceeds 1mm, at this time when using conventional CBN tools for cutting and machining, it is very easy to produce the problem of difficult chip breakage, and there is also a certain impact on the strength of the CBN tool itself in the form of welded tip.

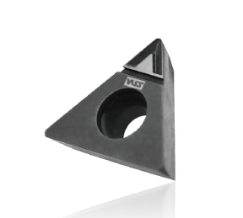

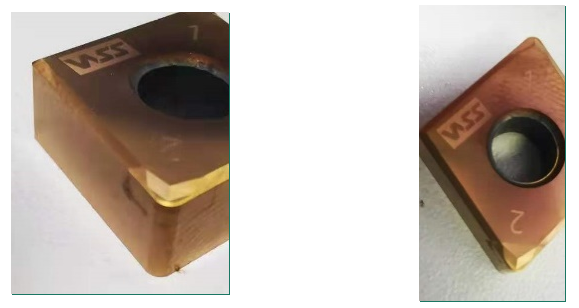

Based on these two points, WSS has developed a new chipbreaker CBN tool after continuous research and study. This means that a three-dimensional shape is machined on the front face of the tool by means of laser engraving to form a chipbreaker groove, which enables smooth chip evacuation during the cutting process and the size of the chips to be controlled. This prevents the chips from wrapping around the workpiece or tool, eliminates the impact on the surface quality of the workpiece during cutting and extends the tool life, resulting in a more efficient and controlled machining process.

The machining performance of chipbreaker CBN tools is well proven in real life machining cases.

01

Case 1

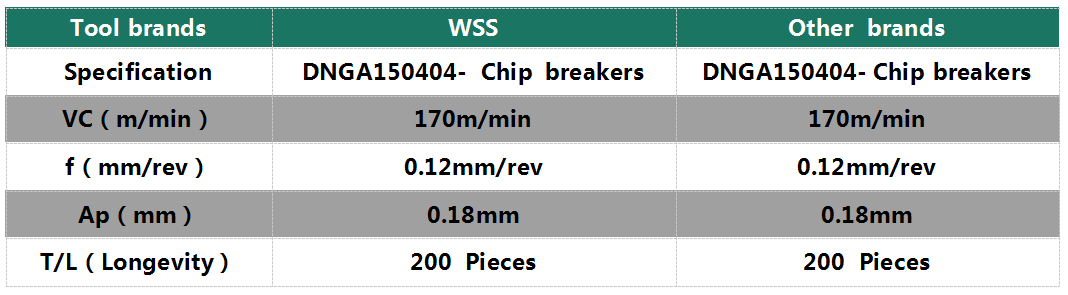

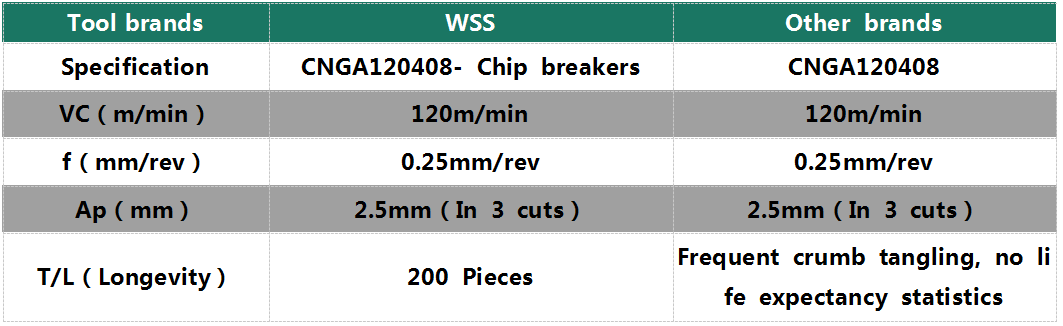

Previously, an imported brand of tool was used without a chipbreaker, which often caused problems with chipbreaking and required constant downtime to remove the chips that were wrapped around the part, resulting in inefficient machining and, more seriously, damage to the surface quality of the part. With the replacement of the WSS chipbreaker CBN tool, the cutting process is smooth and the chip breakage is safe and controlled, eliminating the need to stop and dispose of the chips, improving machining efficiency and meeting the set machining life targets.

02

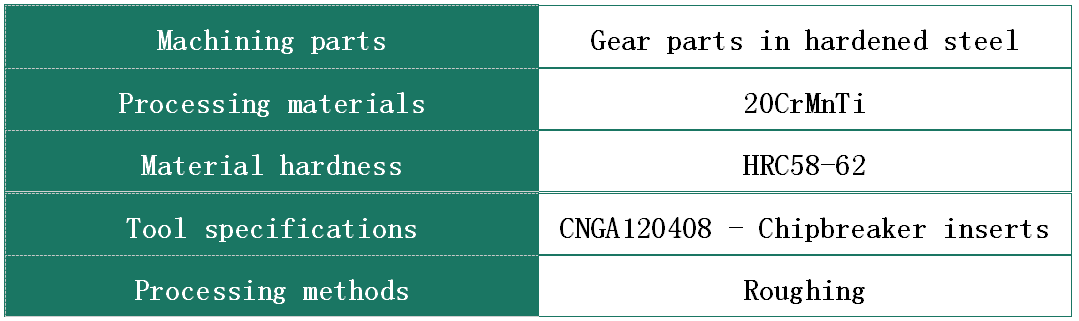

Case 2

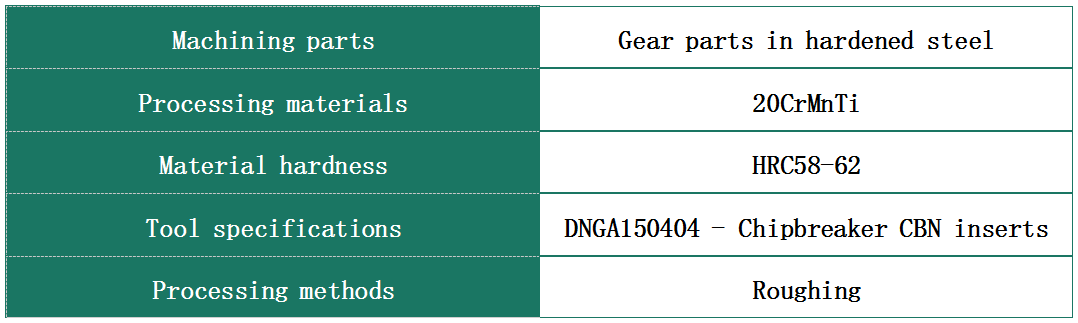

On the same part, this time, we use DNGA150404 CBN inserts with chip breakers to finish turning the end face as well as the outer conical face. When the roughing CBN insert of CNGA120408 roughs the outer conical face, the internal hardness of the gear is no longer as good as the external one and will be relatively lower, which causes the problem of chip breakage during finishing. Therefore we also use CBN tools with chip breakers for machining, which have a good chip breaking effect and a clear cost/performance advantage as a domestic alternative. In addition, WSS will provide you with quick response to the first-line technical support and after-sales service, is your choice of superhard tools.