PCD tools, as a type of superhard tool, are being used in the field of machining in increasing proportions year by year, which is closely related to the rising amount of difficult to machine materials and non-ferrous materials.PCD tools are made of diamond, which is one of the hardest materials, and a tight layer of polycrystalline diamond is applied to the carbide substrate after a special high temperature and pressure process, i.e. PCD tools.

PCD tools are used for cutting non-ferrous metals such as aluminium alloys and copper alloys, as well as non-metallic materials such as fibrous plastics, hard rubber, graphite materials, resin polymer materials, etc. PCD tools can achieve higher cutting speeds and longer tool life than ordinary carbide tools, while also maintaining the surface quality and dimensional accuracy of the workpiece being machined over a long period of time.

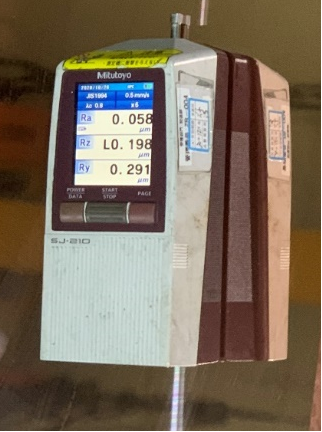

More and more customers are now demanding higher surface quality from their machined workpieces. When WSS uses PCD milling cutters to machine Uc pure copper sheet, the material to be machined is relatively soft and requires a surface roughness Ra value of 0.2μm or less, which poses a considerable challenge. As a rule, soft materials are less likely to have a low roughness.

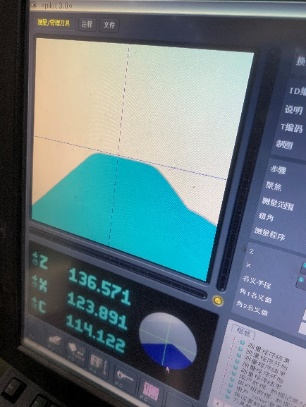

The site fixture uses pneumatic clamping elements, which are not robust, and an old 250mm diameter toolholder is used to clamp a PCD milling cutter for finishing.

WSS combined with the site processing situation, after re-modifying the design, in the blade tip grinding the trimmed edge on pure copper plate processing, the initial test to achieve the required surface roughness.

However, due to the machine tool's longevity, it was prone to reverse deflection after installation and its own poor stability and rigidity, resulting in excessive cutting forces and a slightly higher amount of machining noise.WSS application engineers and the design department conducted a focused analysis of the situation and decided to further improve the tool performance under restricted machine conditions.

In the face of the old cutter and the unstable rigidity of the clamping, we were able to adopt a design with a rounded edge at the cutting edge of the insert, so that the trimmed edge PCD tool is no longer too flat, which effectively reduces cutting resistance, reduces cutting noise and achieves a machining surface roughness of Ra value 0.058 μm. In addition, on the basis of meeting the machining requirements, the tool life is also relatively longer, directly The effect of reducing the cost of machining a single part is achieved.